Our useful FAQ is designed to be as clear as possible. If the information below does not answer your query, please contact us. Our team will endeavour to reply to all questions within 24 hours.

Most common questions

-

Yes. GasStop is designed to be used with regulators rated up to 1.5kg/h, and up to 50 mbar. Please note GasStop will not work with an EFV (excess flow valve) regulator.

-

No, it reads the pressure of the gas under load/usage. It therefore gives a meaningful readout of gas supplies during the consumption of gas (at phase equilibrium). See the question “Is the pressure gauge useful?” for more information.

-

Always check your system for leaks before use. The GasStop pressure gauge is sensitive to minor drops in pressure, making it is a useful tool to use when performing a visual lock-up pressure test, also known as a pressure tightness test or pressure decay test.

This test can only be carried out prior to normal gas usage. During normal gas usage, GasStop will not shut-off the system in the event of a minor leak. During normal gas usage GasStop will only shut-off in the event of a major leak.

To test your system for leaks:

- Set up your system as described in your instructions. Turn off the tap on the gas cylinder. Now turn off your gas appliance(s).

- Now turn the gas cylinder back on. Keep all appliances off for the time being.

- Pump the pressure gauge on the GasStop up and down steadily at least 4 to 6 times. The longer the distance the gas has to travel in the pipe or hose, the more you will need to pump. If insufficient pressure has been created, the GasStop will keep shutting-off the gas supply. Double check at this point that your appliance is still switched off.

- The needle on the gauge should now indicate the gas pressure. If the needle is on zero, or below the red bar on the gauge, then the cylinder tap/valve is not open, GasStop has shut-off, the gas has run out or you have not carried out sufficient pumping. Is the temperature around freezing? Please refer to the Useful Tips section in your instruction booklet.

- Now turn off the tap on the gas cylinder and register the exact position of the needle on the gauge. Wait 60 seconds for Standard Installations and 5 minutes for longer gas systems (e.g caravans, motorhomes, boats and houses).

- At this point, pressurised gas is now held between the GasStop and your appliance(s).

- If the needle has dropped from its initial registered position at the end of the recommended period of waiting time, there is a leak (pressure decay). Do not use the gas system until the leak has been solved or repaired by an approved gas specialist.

- If, after pumping, the needle remains in the same position during the waiting time specified above, you can carefully start using the system.

-

Yes. Each and every GasStop is rigorously tested, referencing ISO 16964:2015. All of our fittings are designed in accordance with EN 15202:2012 and EN 16129:2013. All of our testing is evidenced via a global third-party test auditor.

-

In humid, cool or changeable weather conditions, condensation may appear on the inside surface of the transparent gauge face. This happens as the air trapped inside the gauge condenses, forming small surface water droplets on the plastic casing. Although this is not common, it will not affect the operation of the GasStop. To rectify the problem, remove your GasStop from the gas system and leave the product in a warm and dry location. After a while the condensed water will evaporate and the visual appearance of the gauge will return to normal.

-

If installed correctly GasStop will only shut-off if there is a major problem with your system e.g. a major leak or catastrophic regulator/system failure. If no major leak is present it may be that an inappropriate appliance or regulator is being used. If you are ever in doubt, contact a gas specialist before using your gas.

-

You may notice that in colder temperatures (below 0°C/32°F), an EFV (GasStop) may shut-off more readily when used with higher demand appliances and/or on longer length pipework. For optimum results, try orientating your GasStop so that the gauge is facing the sky.

-

No. GasStop offers up to 6 metres of protection against major leaks (8mm hose/pipe diameter) with an outlet pressure of 6 to 8 bar from your cylinder.

Using the GasStop safely

-

For optimum results we recommend orientating the GasStop gauge towards the sky. GasStop has been designed and tested in this orientation. If space is an issue, the gauge can be orientated no lower than 45 degrees from the sky. If you start to experience unexpected shut-offs, reorientate the gauge back towards the sky. Please note, it is very important not to twist the GasStop during the orientation phase of installation. Orientate the GasStop first, then tighten it to the propane cylinder afterwards.

-

GasStop is not rated for marine use (namely in salt water conditions where ammonia exposure may be present). Please contact a marine gas specialist for further information on marine gas installations.

-

Sudden and/or aggressive movement can disturb the equilibrium of the GasStop shut-off mechanism causing the unit to shut-off unexpectedly. Please be vigilant when travelling on uneven or bumpy roads.

-

We view this as best practice when assessing the safety and integrity of your gas system.

-

To ensure the fitting is gas tight, for most fittings hand tightening is not sufficient. Ensuring your gas appliances and gas system are tight and leak free is essential and recommended across the industry. Always read our instructions before use.

-

If installed correctly GasStop will only shut-off if there is a major problem with your system e.g. a major leak or catastrophic regulator/system failure. If no major leak is present it may be that an inappropriate appliance or regulator is being used. If you are ever in doubt, contact a gas specialist before using your gas.

GasStop features and specs

-

GasStop will only shut-off in the event of a major leak, not a slow/minor leak. GasStop is calibrated to offer major leak protection while allowing the operator to use their low pressure propane system as expected under normal working conditions. To achieve this balance between protection and operating convenience, a major leak is defined as a sudden and dramatic change in the gas flow rate equivalent to a flow rate of 33 litres per minute (l/min) or more. A real world example of a “sudden and dramatic change in the gas flow” is the complete and immediate rupture of a propane hose during a fire or tire blowout. GasStop is also calibrated to shut-off at ≥125% of the guaranteed flow rate (EN requirement).

If GasStop were to be calibrated to shut-off in the event of a minor leak, this would interfere with the ‘normal’ usage/consumption of your gas appliance(s) – GasStop would shut-off every time you use your appliance(s). We have therefore calibrated the device to shut-off for major leaks only.

EN standards state that an LPG shut-off device must be calibrated as described above. GasStop will therefore not shut-off the supply of gas in the event of a minor leak.

-

To achieve a balance between protection and operating convenience, GasStop cannot be calibrated to shut-off the propane system in the event of a minor leak. GasStop will only shut-off in the event of a major leak (see ‘What does GasStop define as a major leak’ FAQ for a full definition of ‘major leak’). However, GasStop can be used to test for minor leaks, here is how:

Always check your system for leaks before use. The GasStop pressure gauge is sensitive to minor drops in pressure, making it is a useful tool to use when performing a visual lock-up pressure test, also known as a pressure tightness test or pressure decay test.

This test can only be carried out prior to normal gas usage. During normal gas usage, GasStop will not shut off the system in the event of a minor leak. During normal gas usage GasStop will only shut off in the event of a major leak.

To test your system for leaks:

- Set up your system as described in your instructions. Turn off the tap on the gas cylinder. Now turn off your gas appliance(s).

- Now turn the gas cylinder back on. Keep all appliances off for the time being.

- Pump the pressure gauge on the GasStop up and down steadily at least 4 to 6 times. The longer the distance the gas has to travel in the pipe or hose, the more you will need to pump. If insufficient pressure has been created, the GasStop will keep shutting-off the gas supply. Double check at this point that your appliance is still switched off.

- The needle on the gauge should now indicate the gas pressure. If the needle is on zero, or below the red bar on the gauge, then the cylinder tap/valve is not open, GasStop has shut-off, the gas has run out or you have not carried out sufficient pumping. Is the temperature around freezing? Please refer to the Useful Tips section in your instruction booklet.

- Now turn off the tap on the gas cylinder and register the exact position of the needle on the gauge. Wait 60 seconds for Standard Installations and 5 minutes for longer gas systems (e.g RV’s).

- At this point, pressurised gas is now held between the GasStop and your appliance(s).

- If the needle has dropped from its initial registered position at the end of the recommended period of waiting time, there is a leak (pressure decay). Do not use the gas system until the leak has been solved or repaired by an approved gas specialist.

- If, after pumping, the needle remains in the same position during the waiting time specified above, you can carefully start using the system.

-

Yes, the two devices can be used together without interference. Unlike GasStop, an Over Pressure Shut-Off valve (OPSO) is not designed for major leak protection. For more information on GasStop vs OPSO valves, you can watch a useful explainer video here.

-

Yes. GasStop can be used with an automatic or manual changeover gas pressure regulator, regulated to a pressure of no higher than 50 mbar with a capacity of no higher than 1.5 kg/h. A GasStop will need to be installed on each bottle attached to the changeover device.

-

GasStop can be used on your gas system whilst driving. Furthermore, GasStop can be installed alongside a crash sensor valve. A GasStop will offer protection against hose rupture/major leaks, a crash sensor valve will protect against collision. The two safety devices fulfil separate yet important functions.

It is important to note that using gas whilst driving is regulated country by country. Please consult with your motorhome manufacturer and the appropriate regulation before using gas whilst driving.

-

Yes, GasStop can be used on regulators rated up to 50 mbar.

-

Yes. GasStop can be used alongside a crash sensor valve, regulated to a pressure of no higher than 50 mbar with a capacity of no higher than 1.5 kg/h.

-

We do not recommend using GasStop for industrial purposes, namely with high pressure appliances. GasStop is only to be used on a pressure regulated system no higher than 50 mbar.

-

GasStop is currently only for use on propane gas bottles.

-

Yes. GasStop is designed to be used with regulators rated up to 1.5kg/h, and up to 50 mbar. Please note GasStop will not work with an EFV (excess flow valve) regulator.

-

GasStop propane devices are rated to operate between -20 degrees C and 55 degrees C. At low temperatures, GasStop may shut-off more readily when used with higher demand appliances and/or on longer length pipework. See ‘Will GasStop operate at low temperatures?’ for more information.

-

No, it reads the pressure of the gas under load/usage. It therefore gives a meaningful readout of gas supplies during the consumption of gas (at phase equilibrium). See the question “Is the pressure gauge useful?” for more information.

-

GasStop will only shut-off in the event of a major leak. A major leak is defined as a sudden and dramatic change in the gas flow rate. GasStop is calibrated to shut-off at ≥110% of the guaranteed flow rate (EN 16129:2013).

If GasStop was calibrated to shut-off in the event of a minor leak, this would interfere with the ‘normal’ usage/consumption of your gas appliance(s) – GasStop would shut-off every time you use your appliance(s). We have therefore calibrated the device to shut-off for major leaks only.

EU standards state that an LPG shut-off device must be calibrated as described above. GasStop will therefore not shut-off the supply of gas in the event of a minor leak.

-

Always check your system for leaks before use. The GasStop pressure gauge is sensitive to minor drops in pressure, making it is a useful tool to use when performing a visual lock-up pressure test, also known as a pressure tightness test or pressure decay test.

This test can only be carried out prior to normal gas usage. During normal gas usage, GasStop will not shut-off the system in the event of a minor leak. During normal gas usage GasStop will only shut-off in the event of a major leak.

To test your system for leaks:

- Set up your system as described in your instructions. Turn off the tap on the gas cylinder. Now turn off your gas appliance(s).

- Now turn the gas cylinder back on. Keep all appliances off for the time being.

- Pump the pressure gauge on the GasStop up and down steadily at least 4 to 6 times. The longer the distance the gas has to travel in the pipe or hose, the more you will need to pump. If insufficient pressure has been created, the GasStop will keep shutting-off the gas supply. Double check at this point that your appliance is still switched off.

- The needle on the gauge should now indicate the gas pressure. If the needle is on zero, or below the red bar on the gauge, then the cylinder tap/valve is not open, GasStop has shut-off, the gas has run out or you have not carried out sufficient pumping. Is the temperature around freezing? Please refer to the Useful Tips section in your instruction booklet.

- Now turn off the tap on the gas cylinder and register the exact position of the needle on the gauge. Wait 60 seconds for Standard Installations and 5 minutes for longer gas systems (e.g caravans, motorhomes, boats and houses).

- At this point, pressurised gas is now held between the GasStop and your appliance(s).

- If the needle has dropped from its initial registered position at the end of the recommended period of waiting time, there is a leak (pressure decay). Do not use the gas system until the leak has been solved or repaired by an approved gas specialist.

- If, after pumping, the needle remains in the same position during the waiting time specified above, you can carefully start using the system.

-

All GasStop models in Europe are calibrated for propane use only – this is clearly stated on the instructions and is marked on the GasStop gauge face.

Autogas very often has a variable and/or high butane composition and may affect the shut-off performance of the GasStop. Autogas is therefore not suitable for use with GasStop.

-

No. Please refer to the information on our packaging or the retailer for case by case compatibility.

-

GasStop is made from high quality, surface treated brass and can withstand being left outdoors. Our gauge face is made from reinforced polycarbonate. As with any brass device, weathering will happen over the course of many years. To slow this process we highly recommend covering your GasStop when not in use. Every GasStop purchased in Europe has a 5 year warranty with proof of purchase.

-

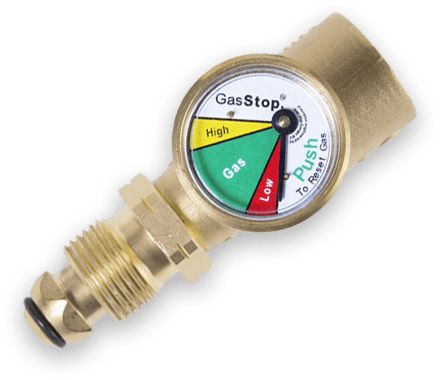

The gas pressure gauge is a very useful, multipurpose tool.

The gas pressure gauge is a very useful, multipurpose tool.- The gauge indicates when the gas cylinder is almost empty (a decline in the vapour pressure curve). The gauge does not indicate the exact amount of propane left in the cylinder.

- A steady pressure reading only indicates that propane is left in the cylinder.

- If the needle is pointing to:

– HIGH: Increased gas pressure

– GAS: Sufficient gas (steady pressure)

– LOW: Almost empty (approximately 30 minutes left of gas use) - As GasStop is directly installed into the bottle there are a few variables that can affect unregulated pressure, namely: temperature, amount of liquified gas vs rate of vaporisation, gas type and gas purity. There may also be other irregularities which affect the pressure reading.

- As per the instructions, it is advised to run the gas for a small period of time to have a better indication of gas level. This allows the propane/pressure to reach something called “phase equilibrium”. Further to this point there is a “vapour pressure curve”, this is why it is recommended to run the bottle for a short while to allow for this process.

NB the gauge is also useful to represent the following:

- Visual evidence of pressure decay (a minor leak) in a lock-up pressure test scenario.

- Visual evidence of high pressure

- Visual evidence of a shut-off

- Visual evidence of an activated and stable system

- Visual evidence of variable/unstable pressure

-

-

In humid, cool or changeable weather conditions, condensation may appear on the inside surface of the transparent gauge face. This happens as the air trapped inside the gauge condenses, forming small surface water droplets on the plastic casing. Although this is not common, it will not affect the operation of the GasStop. To rectify the problem, remove your GasStop from the gas system and leave the product in a warm and dry location. After a while the condensed water will evaporate and the visual appearance of the gauge will return to normal.

-

GasStop will completely (100%) and automatically shut-off the supply of gas in the event of a major leak or catastrophic regulator failure. GasStop must be reset manually, giving the user complete control. A self-equalising EFV (excess flow valve) is often a self-equalising, automatically set, flow limiter, and may not shut-off the flow of gas 100%. Many EFV’s do not have manual resets.

-

The gauge operates much like a consumption gauge (e.g. an oil pressure gauge in a car). See the question ‘Does the gauge read the exact level of gas in the gas cylinder?’ for more information.

-

You may notice that in colder temperatures (below 0°C/32°F), an EFV (GasStop) may shut-off more readily when used with higher demand appliances and/or on longer length pipework. For optimum results, try orientating your GasStop so that the gauge is facing the sky.

-

No. GasStop offers up to 6 metres of protection against major leaks (8mm hose/pipe diameter) with an outlet pressure of 6 to 8 bar from your cylinder.

-

Many propane fuelled generators consume a large volume of propane, meaning they draw a high rate of flow. GasStop is designed to shut-off when that rate of flow exceeds 70 SCFH/75,000 BTU/hr (this is what happens during a major leak). Larger generators may ‘mimic’ this high flow rate scenario, thus effectively tripping GasStop into ‘major leak mode’. It is therefore advised that, if you have a propane fuelled generator, you check it’s propane rating (rated no higher than 70 SCFH/75,000 BTU/hr) before purchasing or using your GasStop.

-

No. GasStop requires several pumps of the gauge to ensure adequate priming.

Quality and compliance

-

GasStop cannot be CE marked because it does not fall within the scope of CE marking. This does not mean the GasStop doesn’t meet the quality demands of CE, what it means is simply the standardised legislation/directive does not cover GasStop at present.

The Pressure Equipment Directive (PED) is the nearest applicable directive and GasStop meets “Sound Engineering Practice” (voluntarily) under this directive. In other words, GasStop meets the maximum requirements (permitted under the directive) required by the PED.

-

“EN 1949:2011+A1:2013; Specification for the installation of LPG systems for habitation purposes in leisure accommodation vehicles and accommodation purposes in other vehicles” is not specifically an LPG equipment approval specification, however it may be pertinent to know how GasStop relates to this EU-wide standard.

According to EN 1949:2011+A1:2013:

6.1.3 If the heating system or any other appliance is intended for use while the vehicle is in motion there shall be means to prevent uncontrolled release of LPG due to accidental disconnection (according to the European Directive 2006/119/EC).”

NOTE There are two alternative types of safety closing devices: excess flow valves, which close when a specific flow of LPG is reached, or crash sensor activated valve, which detects an abnormal acceleration/deceleration of the vehicle (accident) and closes the LPG supply by means of an automatic valve.

GasStop is categorised as an Excess Flow Valve (tested and certified in accordance with the relevant sections of EN 16129:2013). An Excess Flow Valve is a device that protects against major leaks in the event of a rupture (for example, during an accident or sudden system failure). GasStop therefore meets the criteria outlined in EN 1949:2011 + A1: 2013 and EC 2006/119/EC.

Any LPG system inspection and testing processes based on the requirements of EC 2006/119/EC and EN 1949:2012 + A1:2013 will by default include the above clause if relevant.

-

In Germany LPG systems may have to comply with the DVGW worksheet G 607. The LPG system must be tested every 2 years by an LPG expert. This inspection must be confirmed on the test certificate in accordance with the DVGW worksheet G 607. The vehicle owner is responsible for arranging the inspection.

G 607 (Flüssiggas-Anlagen mit einem Höchstverbrauch von 1,5 kg/h zu Wohnzwecken in Straßenfahrzeugen und in Wohneinheiten zur vorübergehenden Nutzung; Betrieb und Prüfung) is an LPG system operation, maintenance and testing technical rules inspection worksheet, and is not specifically an LPG device approval specification, however it may be pertinent to know how GasStop relates to this worksheet and inspection.

Any LPG system inspection and testing processes based on the requirements of EC 2006/119/EC and EN 1949:2012 + A1:2013 will, by default, include EN 1949:2011+A1:2013 clause 6.1.3 if relevant (see “Is GasStop compliant with EN 1949:2011+A1:2013?”).

“Technische Regel – Arbeistblatt DVGW G 607 (A) Juni 2014” is based on the requirements of DIN EN 1949, (see reference document for further information). EN 1949:2011+A1:2013 is a harmonised EU standard and forms the requirements for G 607.

For more information, please refer to the question “Is GasStop compliant with EN 1949:2011+A1:2013?”.

-

Yes. Each and every GasStop is rigorously tested, referencing ISO 16964:2015. All of our fittings are designed in accordance with EN 15202:2012 and EN 16129:2013. All of our testing is evidenced via a global third-party test auditor.

More information

-

How to use

Learn how to use the GasStop in a few simple steps - or watch our explainer video.

-

Quality assured

The GasStop adheres to all revelant standards and has undergone a thorough testing process.

-

Frequently asked questions

Got questions? Find the answers in our FAQ.

-

5 year warranty

Find out more about our 5 year warranty here.